MODULAR CONSTRUCTION METHOD

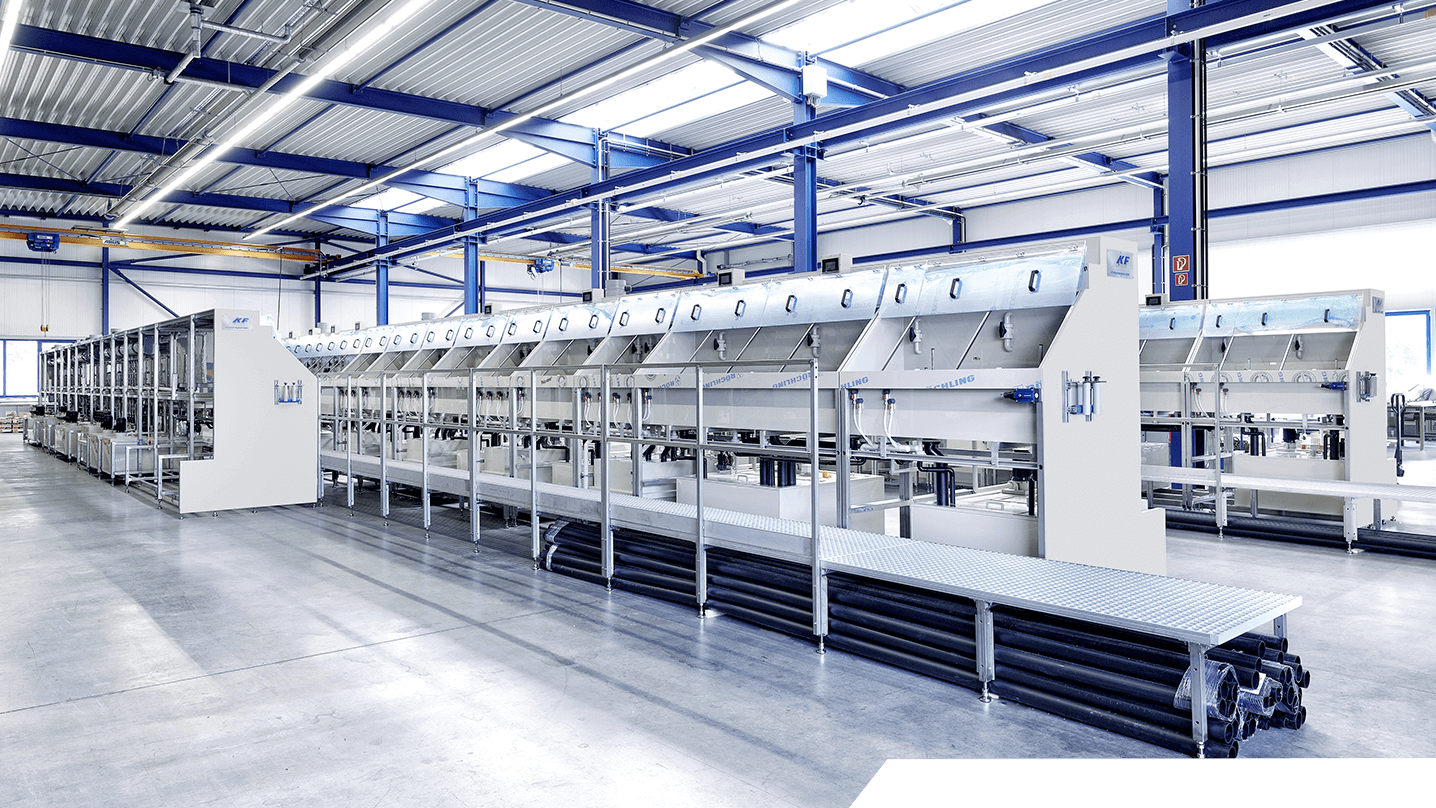

Reel-to-reel electroplating lines from KF

THE BEST EXTENABILITY

Thanks to the modular assembly, we offer you one thing above all: Maximum efficiency with maximum flexibility.

The most flexible reel-to-reel electroplating line in the world

The speed at which requirements for the coating of lines is changing is constantly increasing. With modularization, we can change the coatings in 3-5 days. Existing modules can easily be expanded or replaced with new ones. This way, our customers retain their flexibility and don’t have to plan years in advance.

REDUCED SPARE PARTS INVENTORY

Less is more. Fewer spare parts, more storage space, flexibility, productivity. Or just more time for the essentials.

Previous

Next

Simply better – our renowned interchangeable parts principle

With our spare parts and wear parts philosophy, less = more value. We only use interchangeable parts and modular solutions wherever possible. We give your logistics team a break and create short delivery times by keeping goods at the KF warehouse.

INTERCHANGEABLE PARTS

AKA: The default at KF. Our innovative interchangeable parts principle ensures that your system remains flexible for future expansions.

SYSTEM UPDATES

Your system will always be up to date thanks to bespoke maintenance contracts and system updates.

Maximum flexibility even with existing systems

Customers who have existing systems in place also profit from KF’s innovations. Thanks to the modular principle, innovations can be easily adapted to fit existing systems. Updates can be carried out both mechanically and with control technology. This way, systems don’t become obsolete, but stay up to date.

FAST OPERATION

We know that the best delivery date is yesterday. We already ensure the best time when it comes to delivery.

Previous

Next

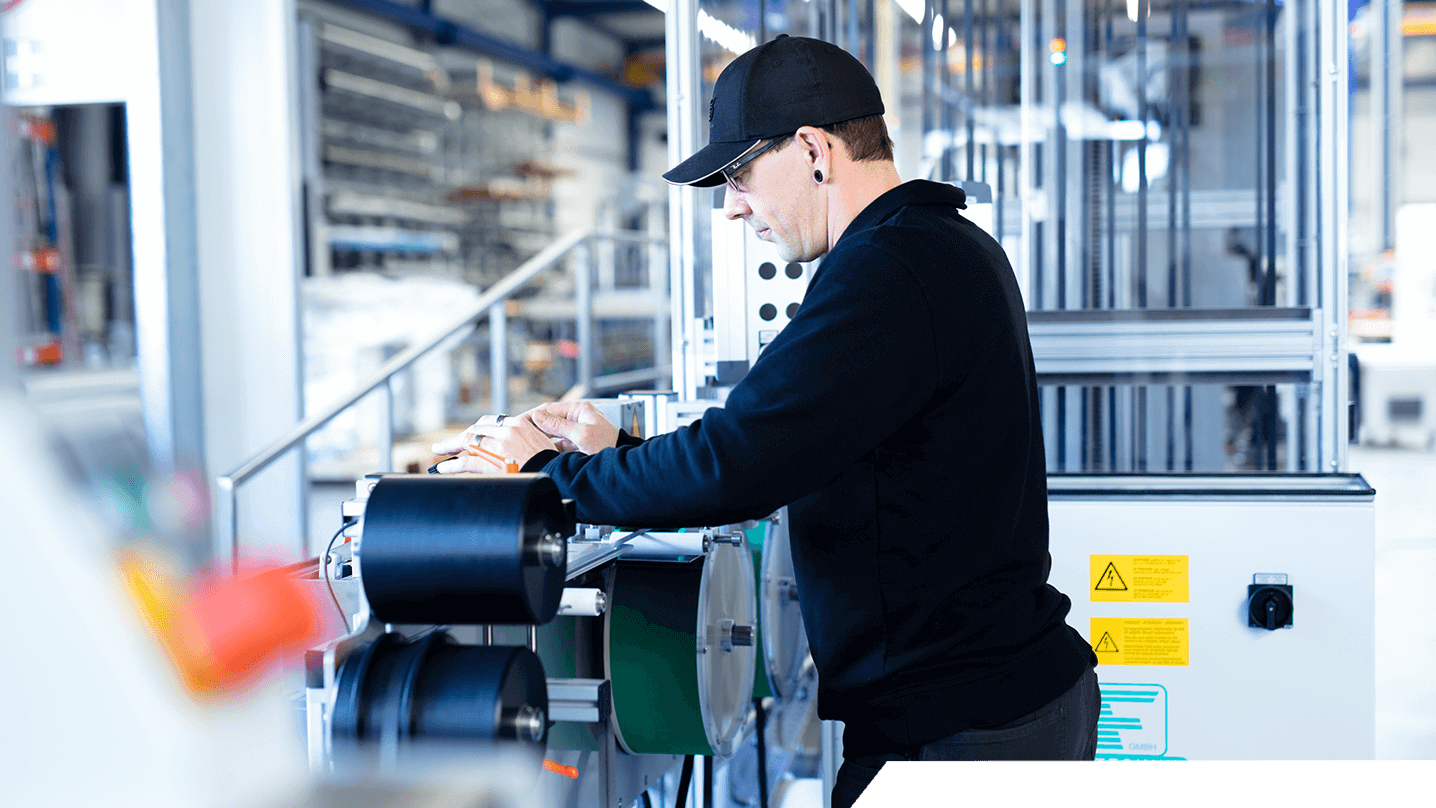

Pre-assembly at KF

Installation & connection

Operation

KF takes care of the pre-assembly all the way to pre-operation.

After pre-assembly, all that’s left to do is install and connect the system modules on your premises. This prevents ongoing production operations from being halted by external personnel.

We guarantee that the system will be up and running as soon as it is put into operation, as it’s thoroughly tested in-house before delivery – both mechanically and electrically.

Pre-assembly at KF

KF takes care of the pre-assembly all the way to pre-operation.

Installation & connection

After pre-assembly, all that’s left to do is install and connect the system modules on your premises. This prevents ongoing production operations from being halted by external personnel.

Operation

We guarantee that the system will be up and running as soon as it is put into operation, as it’s thoroughly tested in-house before delivery – both mechanically and electrically.