AUTOMATIC HEIGHT ADJUSTMENT

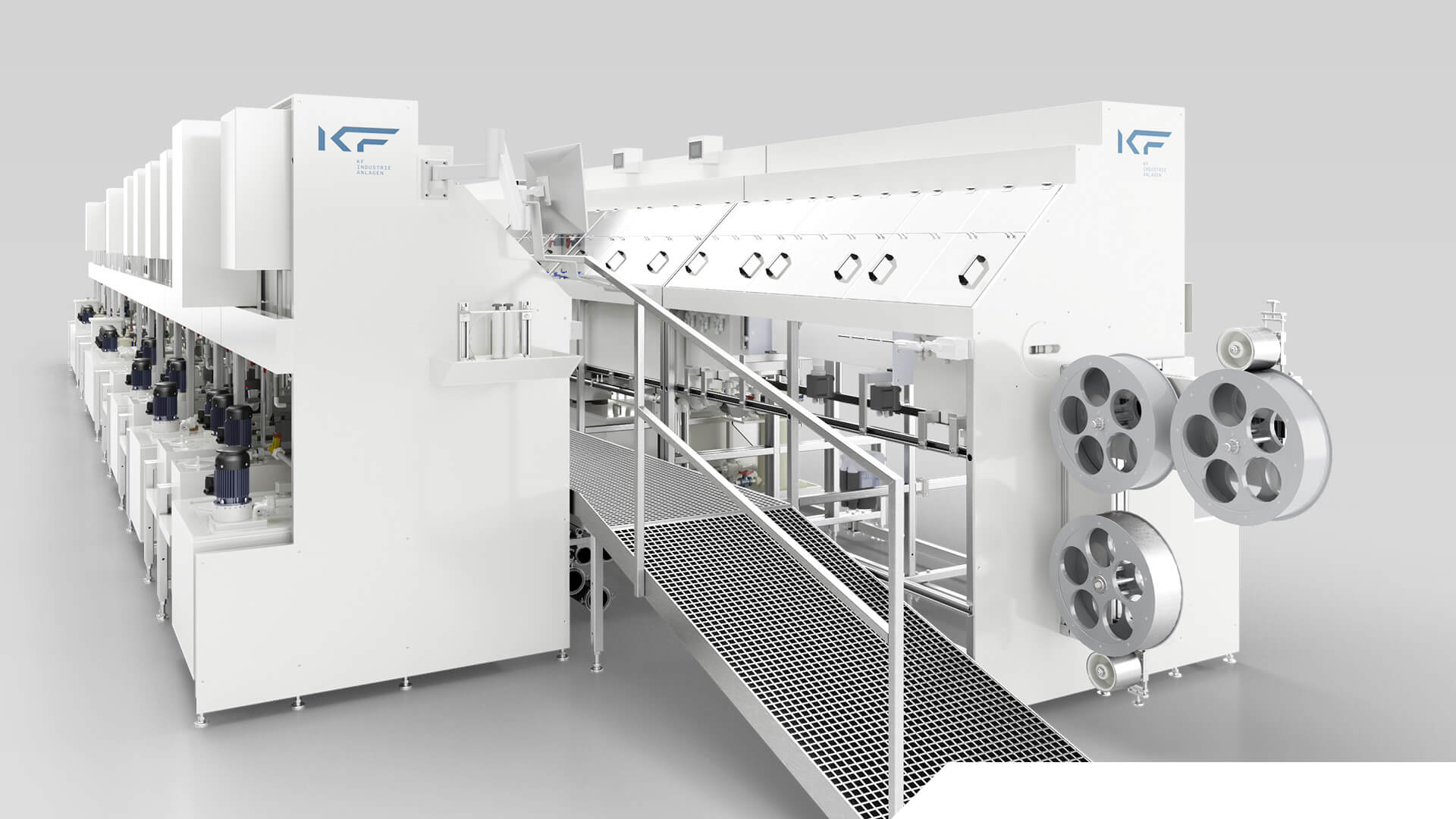

Reel-to-reel electroplating lines from KF

PRECISE SELECTIVITY

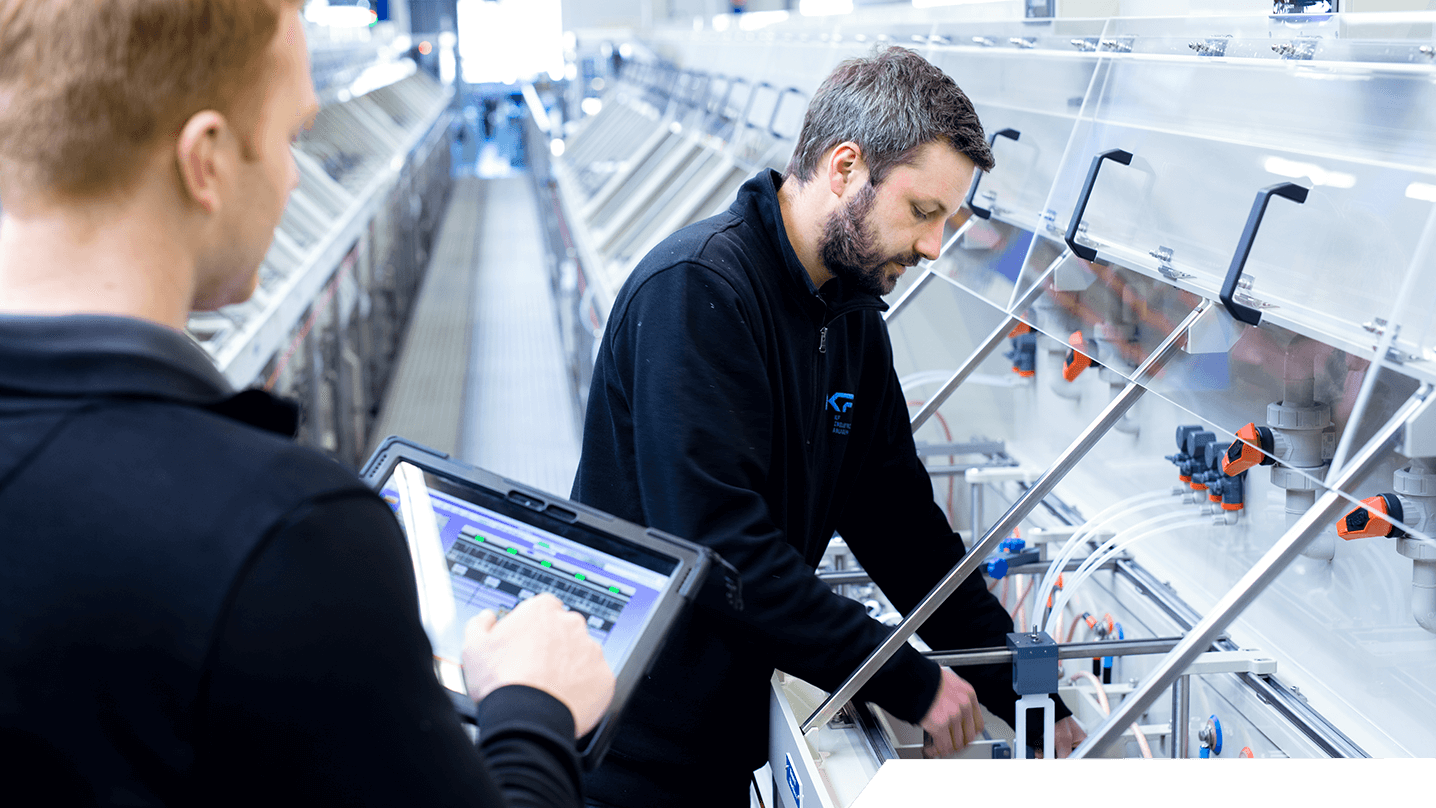

The automatic height adjustment means maximum process reliability with pure precision.

Pure precision thanks to the automatic height adjustment

Pure precision thanks to the automatic height adjustment

From today onward, the precision of the coating no longer depends on employees, but can be reproduced at any time. By using calibrated linear lifting units combined with a recipe-controlled system, cumbersome and time-consuming product re-fitting is a thing of the past. We can change products in under 30 minutes with this technology. Our high-precision driving elements work with an accuracy of +-2 hundredths of a millimeter. In combination with our 8-fold immersion cell, we achieve coating accuracy of up to +-0.2mm.

OPTIMAL REPRODUCABILITY

Manually setting systems is so yesterday. You save time and money with digital recipe management, not just now, but for years to come.

Previous

Next

The best consistency in your production facility

The items are simply loaded from recipe management and released for production. Subsequently, the item-related selectivity is set automatically in each coating unit. This ensures that an item is still coated in the same way months or years later.

During production, target and actual values, as well as system-specific data, are stored together in a batch log, which can be viewed for the desired time period at any time. You as the customer decide which user rights each person/group has. In other words, who exclusively produces and who is allowed to create recipes. With a set product-specific minimum belt speed, you simultaneously ensure a constant output of the systems.

LOGGING

Exceed the requirements set for you.

The amount of parameters that need to be logged is increasing steadily. You, as the customer, decide which parameters should be logged. Thanks to the automatic height adjustment, the specified selectivity is, of course, also recorded.

We can log all product-relevant and system-related

parameters.

parameters.

The range of services offered by KF also includes the recording of additional parameters such as layer thicknesses, cell flow rates, filter pressures and bath concentrations. Get in touch with us.

POKA YOKE

We work on making our systems even more user-friendly day in and day out. We constantly develop ourselves and our systems through an open exchange with our customers.

RISK PREVENTION

UNCOVERING MISTAKES

CONSTANT IMPROVEMENT

INCREASED EFFICIENCY AND SAFETY

Your possible savings

Get inspired by the most cost-efficient reel-to-reel electroplating line in the world. We’d be happy to work together with you to determine your individual possible savings.

SHORT SET-UP TIMES

The automatic height adjustment decreases your set-up time to the minimum.

More time for the essentials

In addition to the reduced personnel costs when changing products, you also benefit from reduced set-up times (under 30 minutes), which increases the system’s productivity even more. So, in future, coating smaller batches will also become an attractive option for your production facility.